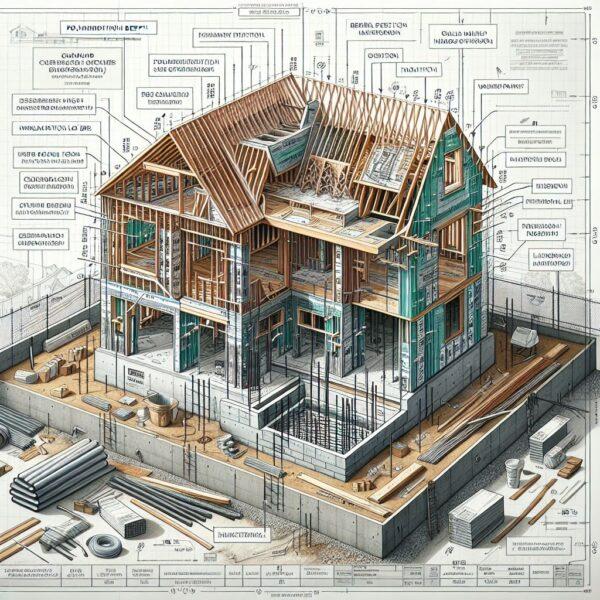

Structural Systems – Structural Loads

Image Credit: Freepik

ARCHITECTURAL ENGINEERING PE EXAM SPECIFICATIONS

Understanding Structural Loads for the PE Exam

As you prepare for the Architectural Engineering PE Exam, a thorough understanding of structural loads is essential. This topic forms the foundation for structural analysis and design problems you’ll encounter on the test. In this article, we’ll cover the key categories of structural loads, how they’re applied, and how to approach them using relevant codes and standards.

What Are Structural Loads?

Structural loads are forces, deformations, or accelerations applied to a structural system. These loads can be either static or dynamic and must be considered carefully to ensure safety, serviceability, and compliance with code requirements. The proper evaluation and combination of loads are critical for structural integrity.

Primary Categories of Structural Loads

The major categories of loads you need to know for the PE exam include:

- Dead Loads (D)

- Live Loads (L)

- Roof Live Loads (Lr)

- Snow Loads (S)

- Wind Loads (W)

- Seismic Loads (E)

- Rain Loads (R)

- Other Loads (e.g., soil, fluid, thermal)

Dead Loads (D)

Dead loads are the permanent, static forces that result from the weight of structural components and fixed equipment. Examples include the weight of beams, columns, floor slabs, mechanical equipment, and other permanently attached systems.

For PE exam questions, these are often given directly or must be calculated based on unit weights of materials (e.g., 150 pcf for concrete).

Live Loads (L)

Live loads refer to transient or movable forces acting on the structure, such as people, furniture, and vehicles. These vary depending on the building use. ASCE 7 provides guidelines for determining minimum live loads in structures (e.g., 40 psf for residential, 100 psf for assembly areas).

Remember: Not all live loads are applied simultaneously. Load combinations account for load reduction factors depending on occupancy and tributary area.

Roof Live Loads (Lr)

Roof live loads are a subset of live loads that apply specifically to roofs and are used to account for maintenance workers or temporary equipment. ASCE 7 provides formulas for calculating Lr based on roof slope and access conditions.

Snow Loads (S)

Snow loads are environmental loads due to the accumulation of snow on a structure. The ground snow load (Pg) is provided in ASCE 7 snow load maps, and the design roof snow load (Pf) is computed using exposure, thermal, and importance factors.

Pf = 0.7 × Ce × Ct × Is × Pg

Key definitions:

- Ce: Exposure factor

- Ct: Thermal factor

- Is: Importance factor

Wind Loads (W)

Wind loads depend on building height, exposure category, wind speed, and shape. ASCE 7 outlines the process for determining wind pressures using either the directional or envelope procedure.

Important factors include:

- Basic wind speed (V) from wind maps

- Exposure categories (B, C, D)

- Importance factor (Iw)

- Topographic effects (Kzt)

Wind pressures act on both the windward and leeward sides of structures and must consider internal pressure coefficients.

Seismic Loads (E)

Seismic loads result from ground motion during an earthquake. These are dynamic and are evaluated based on site class, seismic design category (SDC), response modification factors (R), and base shear.

The base shear (V) is calculated as:

V = Cs × W

where Cs is the seismic response coefficient and W is the effective seismic weight.

Seismic load calculations can be complex. The Equivalent Lateral Force Procedure in ASCE 7 is the most common method used for the PE exam.

Rain Loads (R)

Rain loads occur when roof drainage is blocked and ponding occurs. ASCE 7 provides a method to calculate ponding loads based on geometry and flow blockage assumptions.

Designers must ensure that roofs have adequate slope or internal drainage to prevent structural failure from excessive ponding.

Other Loads

Additional loads include:

- Soil and Hydrostatic Loads: From backfill or groundwater pressure on retaining walls or basements.

- Thermal Loads: From expansion and contraction due to temperature changes.

- Construction Loads: Temporary loads during the erection or modification of a structure.

Load Combinations

Structural analysis and design use prescribed load combinations to account for worst-case scenarios. These combinations are defined in ASCE 7 and differ depending on the load types and design philosophy (Strength Design vs. Allowable Stress Design).

Common strength design combinations include:

- 1.4D

- 1.2D + 1.6L + 0.5(Lr or S or R)

- 1.2D + 1.0W + 1.6L + 0.5(Lr or S or R)

- 0.9D + 1.0W or 1.0E (for overturning)

Use the combination that gives the most conservative (largest) result unless the problem explicitly says otherwise.

Tips for PE Exam Success

- Familiarize yourself with ASCE 7 tables and figures — especially for wind, seismic, and snow loads.

- Know the units: psf (pounds per square foot), kips, pcf, etc.

- Practice identifying which load cases apply to different structural systems (e.g., low-slope roof with snow).

- Understand tributary areas to compute correct loads for beams, columns, and slabs.

- Memorize or tab reference values (like live load reductions, snow load factors) for quick use during the exam.

Structural loads form the backbone of any design and analysis process for architectural engineers. By mastering the principles of dead, live, environmental, and other loads—and understanding how they combine—you’ll be better prepared for both the PE exam and your professional career. Don’t just memorize formulas; practice applying them to real-world scenarios and mock problems to deepen your understanding and improve your speed on exam day.

Let us know if there is anything we can do to help you prepare for the exam.

Structural Loads

Architectural Engineering PE Exam Resources

NCEES

Contact Us

Copyright© All Rights Reserved

EngineeringDesignResources.com prohibits the use or reproduction of this material by any means, graphic, electronic, or mechanical, except in the case of brief quotations embodied in critical articles and reviews. This includes photocopying, recording, taping, or by any information storage retrieval system.

Due to the dynamic nature of the Internet, web addresses or links in these materials may have changed.

Any resemblance in the images in this material to actual people or locations is merely coincidental. EngineeringDesignResources.com prohibits reprinting, copying, changing, reproducing, publishing, uploading, posting, transmitting, or using in any other manner images in this material.